Morson Engine Room

The Morson Engine Room offers an array of advanced manufacturing and metalworking capabilities that extend far beyond those found in traditional workshop environments. The machinery available presents an unparalleled opportunity for individuals to take their design concepts from 3D printed prototype to precision machined component with technology found in high quality workshops. Whether it’s sculpting intricate details with 5-axis CNC milling or crafting precision components through CNC turning, the versatility of these machining tools allows for the production of intricate and customized parts.

Our flat bed CNC routing and waterjet cutting opens doors to a spectrum of creative possibilities, with machines used by artists and architects as well as engineers. Students can explore designs cut from flat sheets with CNC routing. For more resilient materials waterjet cutting offers the ability to precisely cut anything from metals to composites.

TIG welding further expands the capabilities of the metalworking technologies, allowing users to fuse individual metal components into larger permanent assemblies. In this way it’s possible to make designs which are almost impossible to make in one piece.

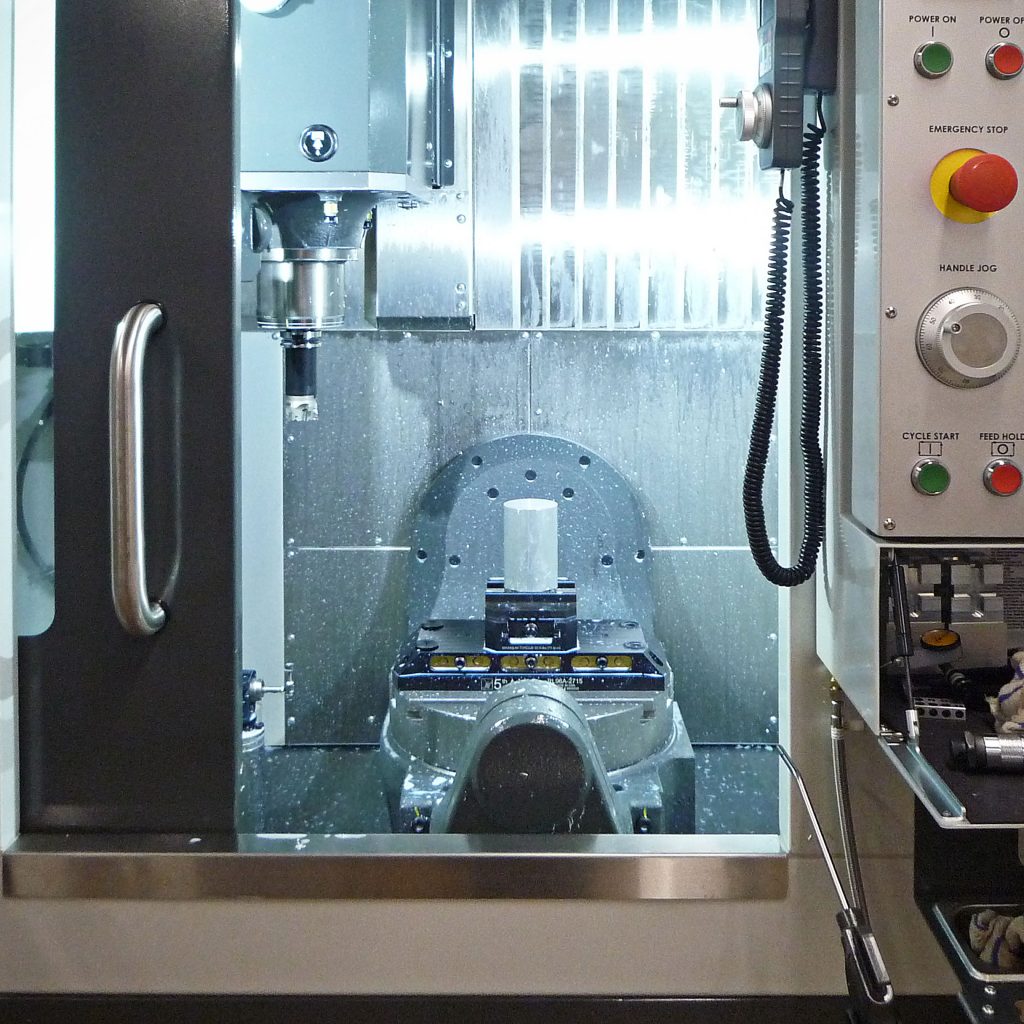

5-axis CNC milling

Our Haas UMC-500 provides both traditional 3-axis machining and powerful 5-axis capabilities for cutting materials such as aluminium, steel, and titanium. After producing a series of training parts under supervision students are free to work independently on their own projects.

The Haas control is widely regarded as one of the easiest to use in the industry, lowering the barrier to entry for students and staff who want to learn CNC machining.

CNC turning

For the production of precision turned components our Haas ST-15Y CNC lathe can work with metre-long bar stock up to 65mm in diameter, and can hold short pieces of material up to 200 mm in diameter.

The lathe uses the same Haas control as the mill so it’s straightforward for users to swap between machines.

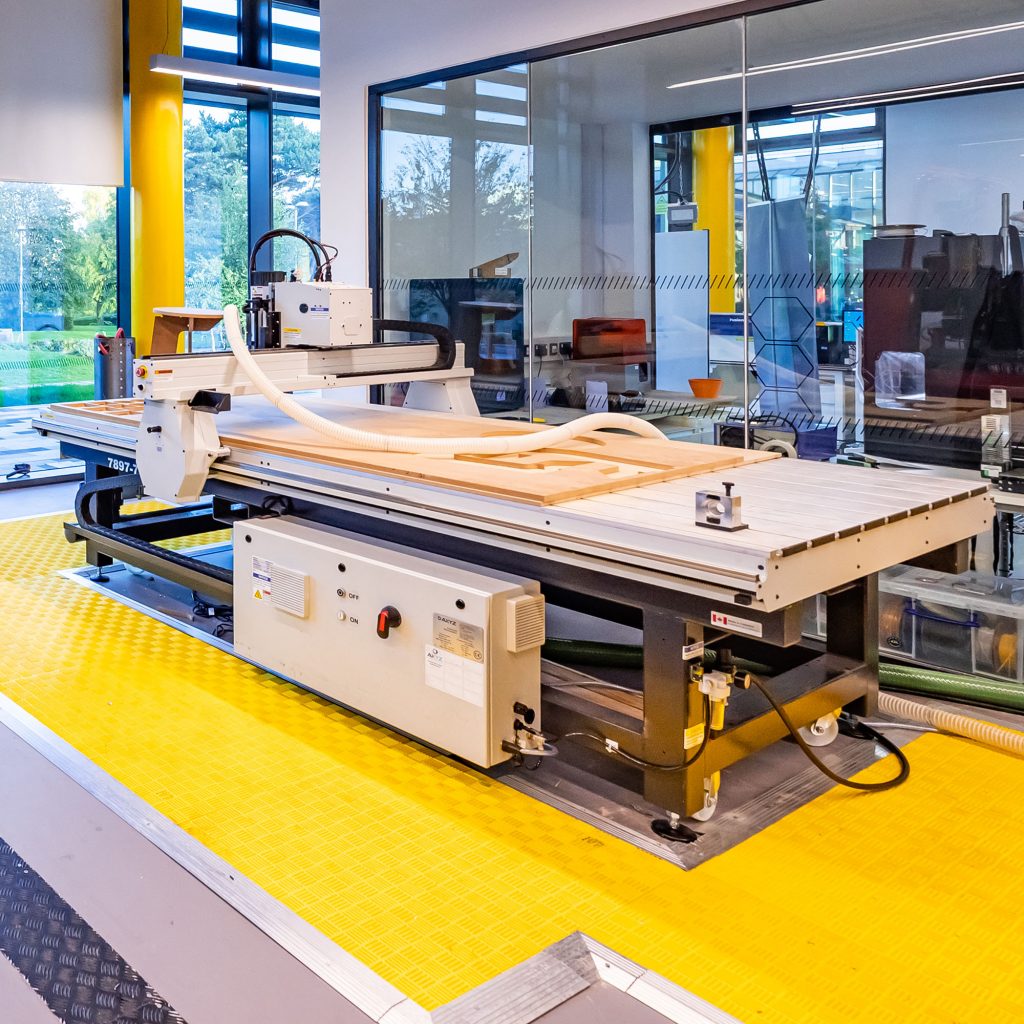

CNC router

A large flat bed CNC router from AXYZ gives sheet material machining capability. The router can cut plywood and MDF with ease, making custom furniture and large scale models simple. Automatic tool changing and a tool setter makes complex designs easy to work with.